Final Project : Spirulina Culture Kit

Team : Marta Porcu – Carmine Montuoro – Nathan Caillé

Spirulina culture kit low-tech and opensource (air pump + Secchi disk + culture instructions) resistant and easy-assembly, realizable with 3d printer.

Project Summary

To respond to the emergency of Kerala, we have proposed a project that aims to solve the problem of food shortages generated by the floods, being capable of guaranteeing the continuity of the livelihood of the displaced population. The project, concretized in a kit (air pump + Secchi disk + culture instructions) but developed on different scales, allows the rapid start of a cultivation of spirulina, cyanobacteria with extraordinary growth and nutritional properties.

Its use is designed for a period of prevention from the emergency: the idea is to develop the culture and awareness of the use of spirulina in parallel with traditional food (not as a substitute for it) so as to have sufficient resources in case of emergency. The final aim is the rapid recovery of everyday life and, at the same time, the preservation of traditional food added to spirulina (native to the area). The proposal has a universal character, is addressed to communities at risk, but also shows potential for those who have malnutrition issues or not easy access to food.

Story Board

Before the emergency:

· The project is sent to the 22 Fablabs in Kerala

· The object is made with the 3D printer

· The kit is sent to the schools

· Spirulina awareness begins

· The inhabitants can create their own basin for the culture

· Spirulina begins to be consumed in parallel with traditional food

· Comes the monsoon season and the flood emergency

· The population is transferred into schools

· Spirulina cultivation has long been in progress

· Spirulina ensures a good level of nutrition in addition to the food of the camps

· Possible increase of spirulina culture

Final KIT (air pump + Secchi disk + culture and tank instructions)

The final object is made up of several elements: the air pump (for the mixing of the water, fundamental for the development of the spirulina), the Secchi disk (a centimetre band with a white base to measure the density of the culture) and instructions for culture and the tank construction.

The most complex project part of our final kit was the air pump, whose latest prototype operates on the principle of air input and output through an elastic membrane in a chamber, stretched by a mechanical system connected to an electric motor. All this is powered by a Lithium battery, recharged by USB via a standard smartphone charger. A variator allows the motor speed to be regulated, which limits the breakage of mechanical parts.

The whole is in the form of a box, which can be fixed to the sides of the culture tank by a 8mm screw system or a rope (the fixing holes allow both to pass through). Simply connect a plastic tube to the nozzle and dip the other end into the spirulina culture.

Fabrication Tutorials

AIR PUMP – CONSTRUCTION

General Overview

Final Prototype – Radio Axonometry

Final Prototype – Isometric views

Preparations

- Have all mechanical and electronic parts ready.

List of mechanical parts

- Use a soldering iron, electric wires (about 1m), stripping pliers, latex balloon (or other elastic surface) and glue.

The pump is composed of 3 main subassemblies: the electronic board, the air pump and the motor. The latter are connected by an electrical circuit and powered by a battery. The pump must therefore be mounted in stages.

Final Prototype – Exploded Axonometric view

Air pomp system

Final Prototype – Air pomp assembly

- Place and attach the nozzle to the front of the pumped air goes to the largest hole.

- Cut a balloon in half at its base or shape to form an elastic membrane in the shape of a half-sphere.

- In the middle of the diaphragm thus formed, create a small hole and pass the back of the piston. (see illustration).

- Position the diaphragm at the back of the air pomp part and secure the seal.

- Then place the complete element on the main plate in the intended position.

Engine assembly

Final Prototype – Engine parts assembly

- Screw the motor into the position provided on the main plate.

- Thread respectively on the engine the rod, the back of the piston, and the lock washer.

- Stick to secure the rod to the engine and the lock washer to the rod. BE CAREFUL NOT TO STICK THE ROTATING PART!

The electronic board

Final Prototype – Electronic components assembly

- On the Electronic support, screw in the dimmer and position the smartphone battery charger card.

- Place the part in the L provided for this purpose on the main plat. Do not stick the smartphone battery charger card to make it easier to solder.

Electrical wiring

- Place the battery in the compartment provided for this purpose.

Final Prototype – Wiring Instruction

- Connect the different electronic parts as shown in the diagram above, paying attention to the polarity. For convenience, it is possible to run the wires through the holes of the main plate.

Finishes

The pump is now operational.

Final Prototype – Plates assembly

- Please now place the different plates to secure the circuit. Note the storage space for the Secchi disk at the back.

Set up

- On the side of your spirulina culture, screw or tie the pump to secure it.

- Provide a soft surface underneath to reduce vibration.

- Place a hose and non-return valve on the nozzle and immerse it in the crop.

- Start the pump 3 to 4 hours a day.

Final Prototype – Pomp fixation

Culture tanks instructions

From our experience in Haugimont we have been interested in spirulina and, as a result, in everything related to it: nutritional values, cultivation, consumption. As our project evolved, through discoveries, mistakes, successes and developments, we have continued and improved in particularly the study of the different possibilities and materials for the realization of the cultivation tanks of this cyanobacteria.

The document, as an essential part of the project, briefly reports all the measures required for the construction of the tanks in which to begin the cultivation, accompanied by the proposal of a tank project realizable according to the techniques and materials of the fablab, with the intention of giving all the information needed to undertake the cultivation, by any means available.

General tips

· Location. It is necessary to respect some rules: not under trees, not in a floodplain, not near a road or an industry and in a flat ground that will facilitate work, as well as proximity to water.

· Coverage. It is often useful, even necessary, to install a greenhouse or at least a roof over the tank, protecting it from excessive rain, sun or cold, and from falling leaves, bird droppings, sand winds and various debris, while at the same time allowing it to « breathe ». The roof can be made of white tent fabric or white PVC-coated polyamide fabric that allows some light to pass through but is able to stop the rain well enough. It can also be made of translucent plastic. If the cover is opaque, it must be high enough so that the pool receives light from the edges. A shadable and aérable greenhouse is ideal in all climates because it allows maximum control of temperature, light, rain and evaporation as well as insects and other animals, dust and dead leaves; it is the most effective protection to reduce water consumption as much as possible in a dry climate.

· Ventilation. Aeration and/or access openings must be provided.

· Number of tanks. It is better to build two or more small tanks than one large: thus one can be emptied (to clean or repair it for example) without losing its contents, and if one of the cultures becomes contaminated, is not in good health or dies, the other will allow to continue and reseed.

· Surface area. 1 m² of tank covers the spirulina requirement of 1 to 5 people depending on the dose. The investment cost per m² decreases when the unit surface area and the surface-to-perimeter of the tanks increase. Narrow tanks (width less than 3 m) are easier to agitate and to cover. A unit surface area of 5 to 20 m² seems practical at the small level (depending on the daily dose of spirulina, and on the productivity of the basins). For artisanal production, the total surface area of the basins will not exceed 50 to 100 m², but a « semi-artisanal » level is possible, which may exceed 1000 m².

· Agitation. Is necessary to uniformise, facilitate the elimination of oxygen and ensure a good distribution of light among all the spirulina. Except in very strong sunshine, you can be satisfied with more or less frequent agitation (a few minutes every hour, at least 4 times a day), manual or by pumps that do not damage the spirulina.

· Plastic film. It allows insulation and impermeabilization, avoids contact between the spirulina and the tank material, and any type of contamination. It also ensures that the temperature of the culture increases more rapidly in the morning and is more slowly dispersed in the evening.

Construction

There are many ways to build a suitable tank, depending on local conditions. The bottom should be as flat as possible, with a very slight slope to a more hollow, easily accessible place (to facilitate emptying). The edges of the tank must be above ground level, to reduce the entry of dust and animals, and at least 20 to 40 cm above the bottom.

Containers, jars, bottles

Translucent containers such as bottles, jars, basins and fruit juice containers (there are 1000 litres of them available) are sometimes used as small tanks. It should be noted that the speed of photosynthesis will appear faster in such tanks because the cultivation environment receives light from several sides and also warms up faster. This may be advantageous, but temperature and pH should be monitored more closely than in regular basins. Agitation in such containers is preferably done by aquarium compressor.

In plastic tarpaulins

The tank can be easily realized with a film layer of at least 0.25 mm, and preferably 0.5 mm, food safe (or at least non-toxic) and UV resistant simply fixed on a wooden frame or tubes of steel or PVC, or supported by a low wall made of planks, bricks, blocks (even if not cemented), stabilized raw earth (pisé). When installing, take into account the high coefficient of thermal expansion of the plastic films (in case of installation in hot weather, there will be significant shrinkage in cold weather, and vice versa). Protect it from direct contact with the floor for example with a « geotextile » felt or two or three layers of used film.

In “hard” (concrete, blocks, bricks)*

The bottom of a cement basin must be constructed as a reinforced concrete slab at least 10 cm thick, of very good quality, on well compacted ground. The edges of the pool can be made of bricks, breeze blocks or reinforced concrete. Avoid sharp angles. It is good to wait a few days, with a tank full of water, before sowing spirulina (otherwise the alkalinity of lime or fresh cement can quickly yellowing the spirulina).

In clay (if we really don’t have any other possibility)*

It is possible to make a tank of digging on 20 cm and making a well packed slope of 20 cm too. If the soil is not naturally clayey, cover the surface with a layer of good quality moist clay, 3 to 5 cm thick, well packed to avoid splits. Fill the edges with baked tiles or bricks, or plastic to avoid splits when the level drops. Spirulina grows very well in a clay tank, but its bacteriological purity must be monitored more closely (increased risk of anaerobic microorganisms at the bottom). The waterproofing is not complete, but it can be improved with even a very thin plastic film.

Fablab Tank

In case none of the above options are available, we propose a very simple “tank” made of wood or plexiglass that must take into consideration the GENERAL TIPS and then: provide for the plastic film and the coverage (among other things).

The idea is to design, through the use of fablab’s techniques, a resistant and easy-assembly structure that allow the cultivation of spirulina. The proposal can be multiplied so as to form ‘structures’ capable of guaranteeing the continuity of the culture, and be placed according to the needs of the users.

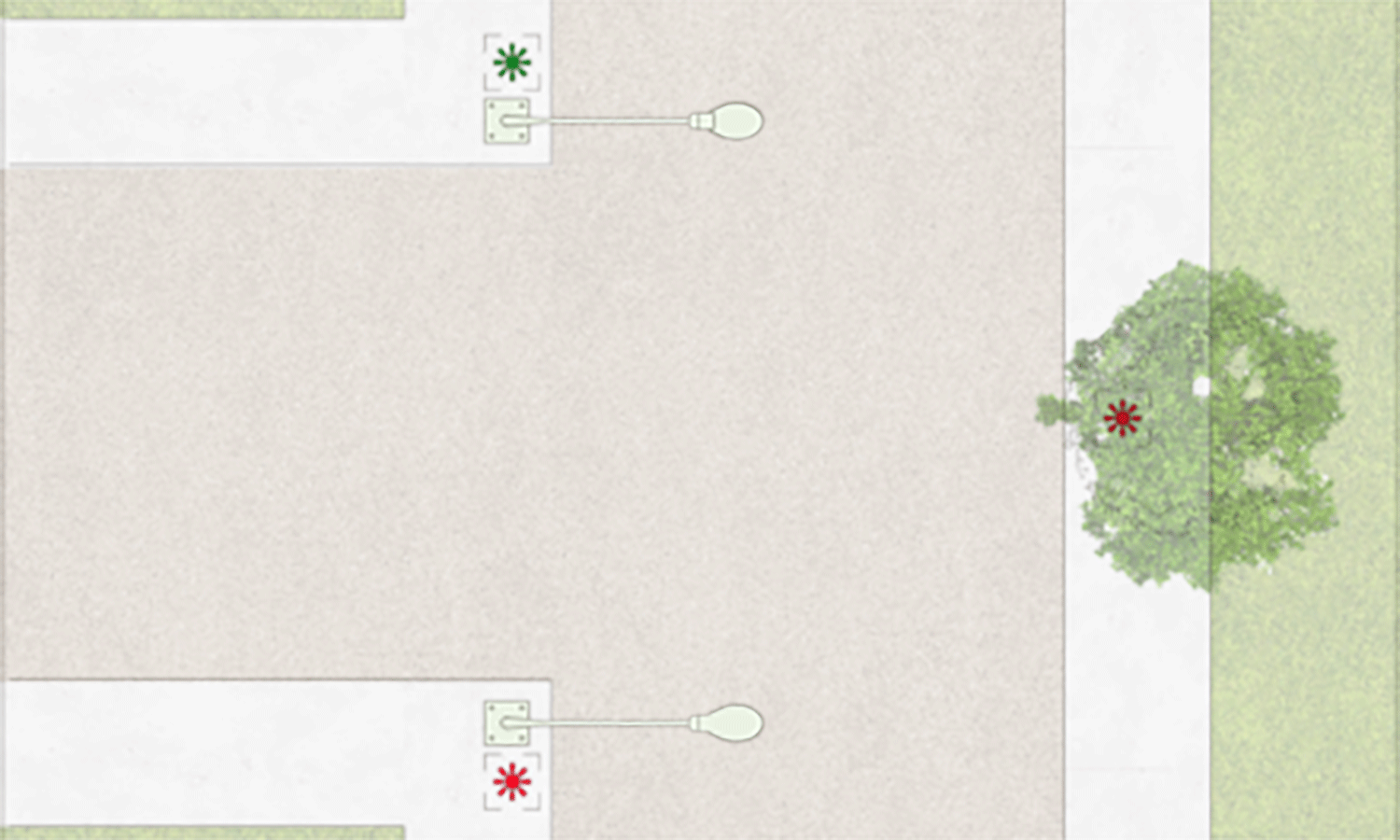

Placement, use and profitability of cultures

We know the average capacity of a refugee camp is +/- 300 people. In the worst case, the population does not exceed 1600 people. Knowing that 1m² makes it possible to feed a person in a healthy way, it takes about 300m² of culture for an average camp, up to 1600m² for a maximum size camp. Faced with this spatial challenge, we then propose for the FabLab Tank a spatial layout that facilitates and optimizes culture.

Saving space

We therefore have a linear width of 5m of cultivation on 3.5m on the ground. This saves 30% more culture space than if we only occupied the ground. This amounts to an area of:

For an average camp:

| Required surface area | People feed |

|---|---|

| 3,5 | 5 |

| 210 | 300 |

210 m² (on the ground) of cultivation

For a camp max size:

| Required surface area | People feed |

|---|---|

| 3,5 | 5 |

| 1120 | 1600 |

1120 m² (on the ground) of cultivation

Attention: the height limited to 3 meters high allows fairly easy access to the basins, to guarantee the stability of the structure and thus limit the risk of accidents. *

Question of sunshine

The staggered arrangement makes it possible to optimise the sun exposure of the culture. Indeed, spirulina needs light to develop, but no strong direct radiation that could kill the strain. As we can see above, the arrangement allows to give the culture a good sun exposition in the morning and in winter, when the sun is low its soft rays; and to hide for the most part (except the last one at the top that it will be necessary to hide) the tank in summer and in the midday (too hot) sun.

The staggered arrangement makes it possible to optimise the sun exposure of the culture. Indeed, spirulina needs light to develop, but no strong direct radiation that could kill the strain. As we can see above, the arrangement allows to give the culture a good sun exposition in the morning and in winter, when the sun is low its soft rays; and to hide for the most part (except the last one at the top that it will be necessary to hide) the tank in summer and in the midday (too hot) sun.

Spirulina culture starting instructions

Cost And Time

The purpose of the project is to offer a complete starter kit for spirulina culture at the lowest price. The whole kit (without the battery*) costs around 15€ (costs based on the selling prices of the components in Belgium), distributed as follows:

– Electronic components: 5€

– Electric motor: 6€

– PLA: +/- 4€

*The choice of battery will depend on local availability. Battery prices can vary significantly depending on their type, quality and origin. The reuse of mobile phone batteries is a possibility allowed by the prototype (integrated 5V phone charger).

The time of production is very dependent on the efficiency and number of machines available in the FabLab of fabrication. On average, a prototype will require 1 hour of all-inclusive handling (downloading files, creating the G code, starting printers and recovering parts). The total printing time is about 18 hours (printing time of all parts cumulated). The distribution of prints on several machines reduces this time up to 7 hours of printing (simultaneous printing of parts). The assembly of the prototype will be left to schools for educational purposes (discovery of electronics and FabLab dynamics).

Source internet and links

Inspiration: “nomade des mers”

https://www.youtube.com/channel/UCOWvvmXlP9f0Nrl2DQtyLTQ

Composition and benefits of spirulina

https://www.antenna-france.org/

https://www.antenna-france.org//wp-content/uploads/2014/06/spiruline-aspects-nutritionnels.pdf

http://vegecru.com/spiruline?fbclid=IwAR2pAtAscEGZOrRhR8AT8Nd9wZBOoYN4FDVC_-LBkijGXfCaf_BlY5jJR-0

Info spirulina culture

http://lowtechlab.org/wiki/Culture_de_la_spiruline/en

Contacts for information on the spirulina culture and its use to fight malnutrition in India:

http://www.algonauts.org/algonauts/3arthi.html

http://www.spirufoundation.org/

https://www.youtube.com/watch?v=4_3fyCtQfWk

https://oferr.org/tbdonations/livelihood-training-through-spirulina/

NHP, National Health Portal, India:

Spirulina request:

https://www.teramer.eu/complements-alimentaires/

Limits and improvements

The project is ambitious and the spirulina is a vast subject to study, the proposal responds to the fundamental technical needs linked to the beginning of a culture of the spirulina. The kit and the tank project can certainly be improved through more contacts with spirulina producers and on-site study.

Final prototype

Process : Spirulina Culture Kit

Team : Marta Porcu – Carmine Montuoro – Nathan Caillé

Spirulina culture kit low-tech and opensource (air pump + Secchi disk + culture instructions) resistant and easy-assembly, realizable with 3d printer.

The working process developed during the fablab course was characterized by several significant phases, which characterized the development of the project until the end.

Start of DIGITAL FABRICATION STUDY 1

October 2, 2018

The beginning of the course marked our approach to the materials and techniques of the FABLAB, to the mutual knowledge and to the first analyses concerning the emergency context in Kerala.

This period was characterized by an interdisciplinary immersion aimed to analyze our field of intervention, developing a global approach based on observation at several scales (constraints, needs, sustainable development and innovation, physical, social, economic and spatial context). Even if we start from the concrete case of Kerala, particular attention was given to the widening in other situations (other locations, other temporalities, other cultures).

DEFINITION OF PROJECT THEMES AND FORMATION OF GROUPS_ FLOATING SPACES

October 19, 2018

Since the formation of the project themes and the groups we have worked on floating spaces as a response to the problems generated by the floods. Our group has been interested in the design of shared gardens as a response to the food deficit and started their design, studying the principle of Archimedes, modularity and usable materials.

This first project suggestion was born with the intent to guarantee safe collection areas and the continuity of food supply during and after the catastrophe, at the same time it aimed at maintaining the sense of community, working therefore also at a preventive level.

First concept of the project

1ST SKYPE WITH KERALA’S FABLAB

October 26, 2018

The first conversation with the Kerala Fablab was one of the most important experiences for the process of the entire course. The exchange with the local contacts allowed us to test our working hypotheses, to have a wider knowledge about the materials that can be used on site, to clarify ideas, to better understand needs and issues. Our interlocutors have understood our sincere interest and our willingness to improve the proposals on the basis of their advice.

The theme of floating spaces was welcomed in a positive way and with interest. We were surprised to hear talk of prevention rather than immediate and short-term responses.

WORKSHOP IN HAUGIMONT – START OF PROTOTYPES

November 5 – 9, 2018

During our first workshop’s day we understood that our floating project was not a relevant system for 2 reasons:

– a project scale unsuitable;

– an error regarding the temporality and the functionality of the module (the residents of the affected areas will be forced to leave their homes: the plants may remain safe, but the lack of people to maintain them makes them unsustainable).

First concept’s sketch

First drawing of the floating module

Section of the module

As a result of this twists and turns we started to develop an answer to the the food deficit that would respond to all the characteristics related to the FABLAB and to the real issues in India. Since this moment we srudied the spirulina as a response to the problem identified, experimenting and using rapid prototyping to develop an initial test of design concept.

The inspiration for this project came from Corentin de Chatelperron, a low-tech engineer who challenged himself to live in self-sufficiency on his raft producing, on a low-tech technology base, a spirulina bioreactor. The discovery of the spirulina , a freshwater cyanobacterium with extremely high nutritional values and an extremely fast growth rhythm, appeared to us as a sustainable answer for the production of food with very rudimentary means. This is where our studies on this cyanobacterium and everything related to it began: nutritional values, cultivation and consumption.

« Nomade des mers » – a good exemple of spirulina’s benefits

« Nomade des mers » – easy and lowtech spirulina culture

Our first project focused on the prototipation of a lowtech culture tank: the whole system was designed to be reliable, fast to produce, easy to assemble and, above all, reproducible throughout the FabLab network in Kerala and around the world.

PROTOTYPE 1 : MDF – CNC CULTURE TANK – 0.25m²

Measure: 50cm x 50cm – capacity of 0.25m², was therefore made on MDF panels at the CNC. A food film would be used to guarantee the waterproofness of the culture tank and the good condition of the wooden walls.

This first prototype gave us several knowledge:

– the precise use and performance of a CNC;

– mistakes on assembly issues;

– ergonomic problems;

We then corrected these shortcomings and produced a new laser-cut prototype.

FabLab CNC making the first prototype

Study of the tanks structure

First « scale » concept for the tanks

Final tank proposal at the end of the workshop

PROTOTYPE 2: MDF BIOREACTOR BOX – LASERCUT – 0,014m²

LaserCuted prototype – Study of the assembly

Prototype 2 – Top view

Prototype 2 – Iso view

Haugimont Presentation

AFTER HAUGIMONT_FIRST KIT PROTOTYPES

November 13 – 30, 2018

Since our visit to Haugimont our project has evolved from the idea of a tank for the spirulina culture to the progect of a small kit containing all the tools necessary for its cultivation (pump and electrical circuit, Secchi disk) developed on 3 different scales: 1. a energy system 2. a+b energy system + container; 3. a+b+c electronic system + container + cultivation tank proposal.

Our work progress has developed on several fronts:

Theoretical

– interview with a biologist and nutritionist;

– reading of scientific texts: Grow your sprirulina from J. P. JOURDAN and Spirulina Nutritional Aspects from J. FALQUET and J. P. HURNI.

Study of an electrical air pomp

Practical

– e-mails to various associations in South India that cultivate and organize courses to teach spirulina culture in order to better understand the real feasibility of the project_ no answer;

– e-mails to European companies to request collaboration and the sending of spirulina strain_ positive response from Teramer Montpellier.

Asking some information about spirulina in Kerala

Asking a request for a spriulina strain

Technical:

– study of electrical and mechanical circuits;

– prototyping.

Making the solar pomp prototype

Final view of the solar prototype

AIR POMP PROTOTYPE 1

The first prototype was a homemade air pump made from a small number of electronic parts and recycled materials. This « as simple as possible » approach has allowed us to focus on the essential questions of our purpose: What type power supply? How to create the air movement? How to transmit energy from the motor to the pump?

On a wooden plate, we placed a 9V battery, fixed a 6V DC motor and a switch. This pump also led us to create an air piston system with a plastic milk bottle cap, a sewing button and a balloon. This process will continue until the final draft. The prototype was functional, but it could be made more reliable and reduced to a smaller scale.

First try of a lowtech air pomp

Prototype 1 – Axonometry

Prototype 1 – Production

Prototype 1 – Working experience

AIR POMP PROTOTYPE 2

The second prototype was the opportunity to design the first base of our pomp (laser cut), and to replace the traditional wires with real mechanical parts printed in 3D. The prototype works in the short term, but the 3D parts eventually give way because of their fragile nature.

They will be improved later on.

Prototype 2 – Axonometry

Prototype 2 – Production – Top view

STL – 3D plate parts view :

STL – 3D engine parts view :

2ST SKYPE WITH KERALA’S FABLAB

December 4, 2018

The second skype with the local FabLab clarified some doubts about spirulina cultivation in India and, in particular, in Kerala. Our project proposal was defined as a good solution to develop based on the actual eating habits of the population and the climatic conditions of the area.

In particular, we can identify 2 key points that emerged during the conversation:

- Spirulina is not a specific food o Kerala, but remains usable in the rest of India (in the diet of which it is present) or, more generally, where there are problems of malnutrition > raise awareness and make spirulina known in Kerala through a proposal for domestic/school culture.

- The hypothesis of use of solar panel used to operate the pump could be problematic due to the lack of light and sunlight during the rainy season > use of an alternative energy system.

FINAL STEP

December 21, 2018 – January 10, 2019

The pre-exam was marked by the implementation of our kit, realizing some lacks and some weaknesses: through the creation of a illustration we have explored the potential benefits of our project.

Scenario

AIR POMP PROTOTYPE 3

The third prototype finally fixes the electrical and mechanical principle of the pump. The prototype is powered by a rechargeable lithium battery, which for reasons of convenience and universality is recharged with a telephone charger. The pump’s service life is no longer determined by the current but by the mechanical parts.

Air Pomp System

Prototype 3 – Electrical System

Prototype 3 – List of different parts

Prototype 3 – Exploded view – Cost and Time analysis

Prototype 3 – Working experience

Prototype 3 – Final Picture

STL – 3D plate parts view :

After our last presentation and the following comments from the group, we improved some aspects of our project:

– real functionality of the kit: the arrival of the strain of culture, donated to us for our research by Teramer Montpellier, allowed us to start the culture and test the final prototype;

– study of the nutritional values of spirulina: creation of various recipes that allow us to better understand the nutritional properties of the cyanobacterium compared to the diet of Kerala and, more generally, of India.

| Day 1 | Day 8 |

|---|---|

|

|

Culture A – December 2018

Except where otherwise noted, this work by ULB / DFS-Q1 / 2018-2019 is licensed under a

Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.