A foldable boat, low-tech, opensource and easily constructable with one single sheet of wood.

Project Summary

This project takes place in the context of the floods of August 2018 which occured in Kerala in India. One of the main problems caused by this disaster was the fact that people were unable to move from their house because of the high level of water, unable to reach the safety camps, in danger of getting drowned and exposed to infections and diseases because of the water. To confront these problems, we proposed a project of a transport usuable for some days, foldable and unfoldable, esealy constructable, allowing them to be safe, from drowning and infections, and to leave their house to reach the camps. The project will help them to prevent an eventual disaster, but nonetheless will be usefull in daily life if they need it. Also, it will be possible to share the project with other countries or regions experiencing similar situations.

This project takes place in the fablab by cutting the model with a CNC, and by sharing the prototype trough the network. The boat is made of a single sheet of wood, with standard sizes (244x122x0,6), and junctions made of rubber.

Price

- MDF : +/- 20 euros

- Rubber : new : 5 euros // recuperation : 0 euros

- Bolts : 6 x 10 bolts : 14,34 euros

- Bamboo stick : 0 euros

The project will cost approximately 40 euros

Timing

- Cutting the plank of wood with the CNC in the fablab (duration : +/- 1h)

- Assembly of rubber joints (duration : +/- 1h)

- Total production : +/- 2 hours

Numbers

- Number of persons per family in India : 4-5 > 1 boat = 2 adults and 2 children

- Weight : 250 kilos (family + stuff)

- Numbers of boat : targeted operation

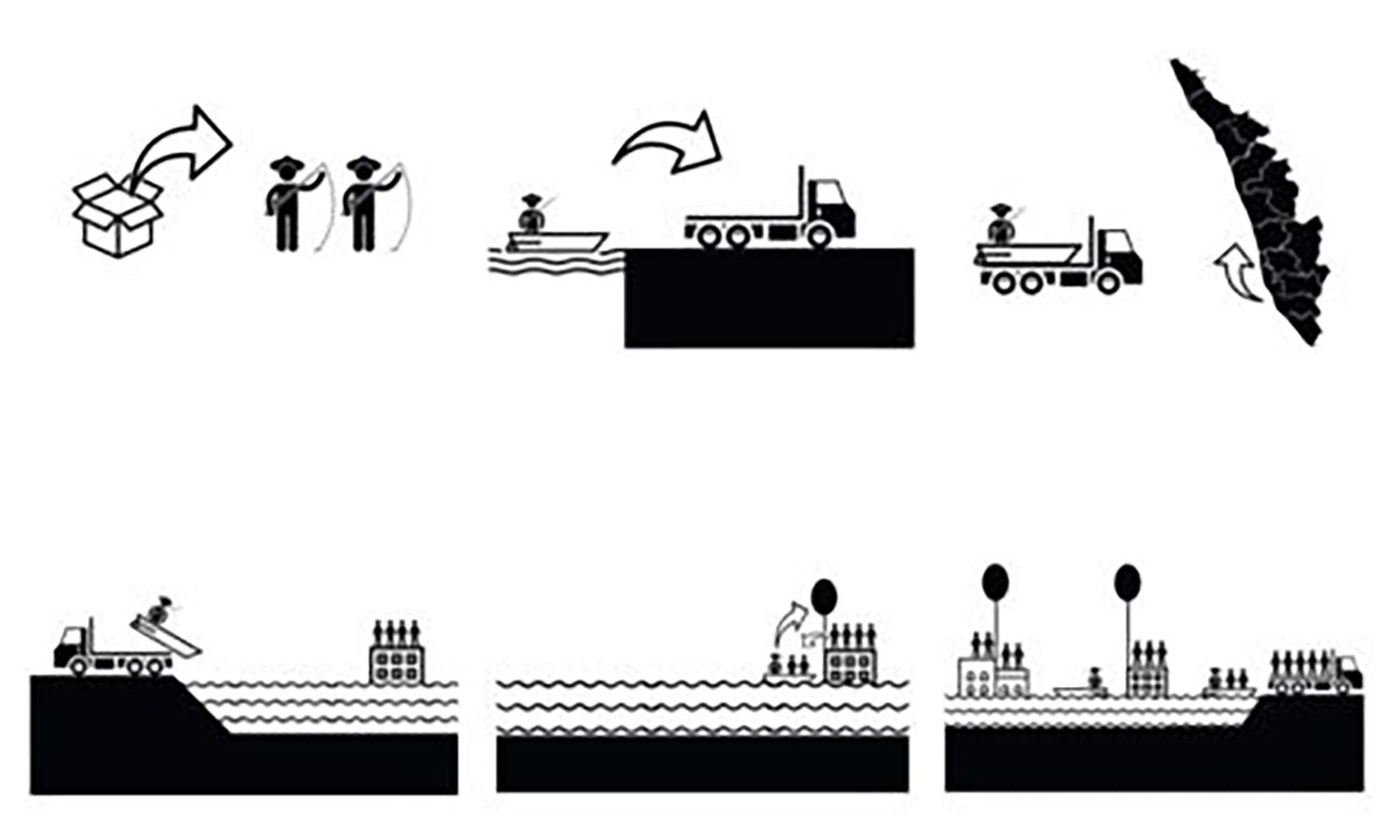

Storyboard

Manufacturing tutorial

To follow :

What works and what does’nt work today ?

Working things

- The assembly between wood and rubber works

- The boat is waterproof

- The folding system works

- It is made out of accessible and cheap materials

- It is easy to produce

Non working things

- MDF is not the best wood to use for a boat, because sometimes it can suffer from some deformation in contact with water.

- The bamboo stick could be another object usefull for the boat

What’s next for the project ?

Actually, we would like to improve it to get to an optimized boat.In addition to that, Daniel one of our contact, is now very enthusiastic about the idea of our project and would like to create a collaboration between our work on the boat here at the ULB fablab and his own class of carpenters. But moreover, he wants to do it also with the Isle-sur-la-Sorgue (South-East of France) fire brigade so that they can reproduce our project and use it in a professional way and maybe spread it trough the whole profession.

Project’s files

Sources and references

A foldable boat, low-tech, opensource and easily constructable with one single sheet of wood.

Introduction

This project takes place in the context of the floods of August 2018 which occured in Kerala in India. One of the main problems caused by this disaster was the fact that people were unable to move from their house because of the high level of water, unable to reach the safety camps, in danger of getting drowned and exposed to infections and diseases because of the water. To confront these problems, we proposed a project of a transport usuable for some days, foldable and unfoldable, esealy constructable, allowing them to be safe, from drowning and infections, and to leave their house to reach the camps. The project will help them to prevent an eventual disaster, but nonetheless will be usefull in daily life if they need it. Also, it will be possible to share the project with other countries or regions experiencing similar situations.

Analyse of context and indentification of problems in Kerala

By analising the situtation of Kerala trough pictures, texts and testimonys, we identified several major problems due to the floods :

- Drowning

- Loss of personal property

- Movement difficulty

- Infections, injuries, diseases

Skype with Kerala

With the team of DFS, the fablab of ULB, we made a first contact with fablabs of Kerala, in order to ask them questions about the situation and to understand better what was at stake by listening to them.

During the discussion, we understood that boats were a true necessity when the flood strikes. It would help them to escape their house and reach safety camps, using it for a duration of 2-3 days. Also they gave us a reference for our project : Oru Kayak. Then we realised that with the project of the boat we were on a good path to help them.

Prototype 1.0

References

Several references caught our attention, from nature to craft boats :

- Victoria water-lily

Victoria is a genus of water-lilies, with very large green leaves that lie flat on the water’s surface. It can have a leaf up to 3 metres in diameter.

- Coracle

The coracle is a small, rounded lightweight boat traditionnaly used in India as fishing boats. The structure is made of a framework of split and interwoven bamboo and waterproofed by using resin and coconut oil.

Prototypes

So, we started prototyping with the idea of a boat made with a wood framework and covered with a waterproof tarpaulin.

First prototype :

This first test helped us realised the number of branchs we would need to build the framework structure. The main problem here was the junctions which were not solved.

Second prototype :

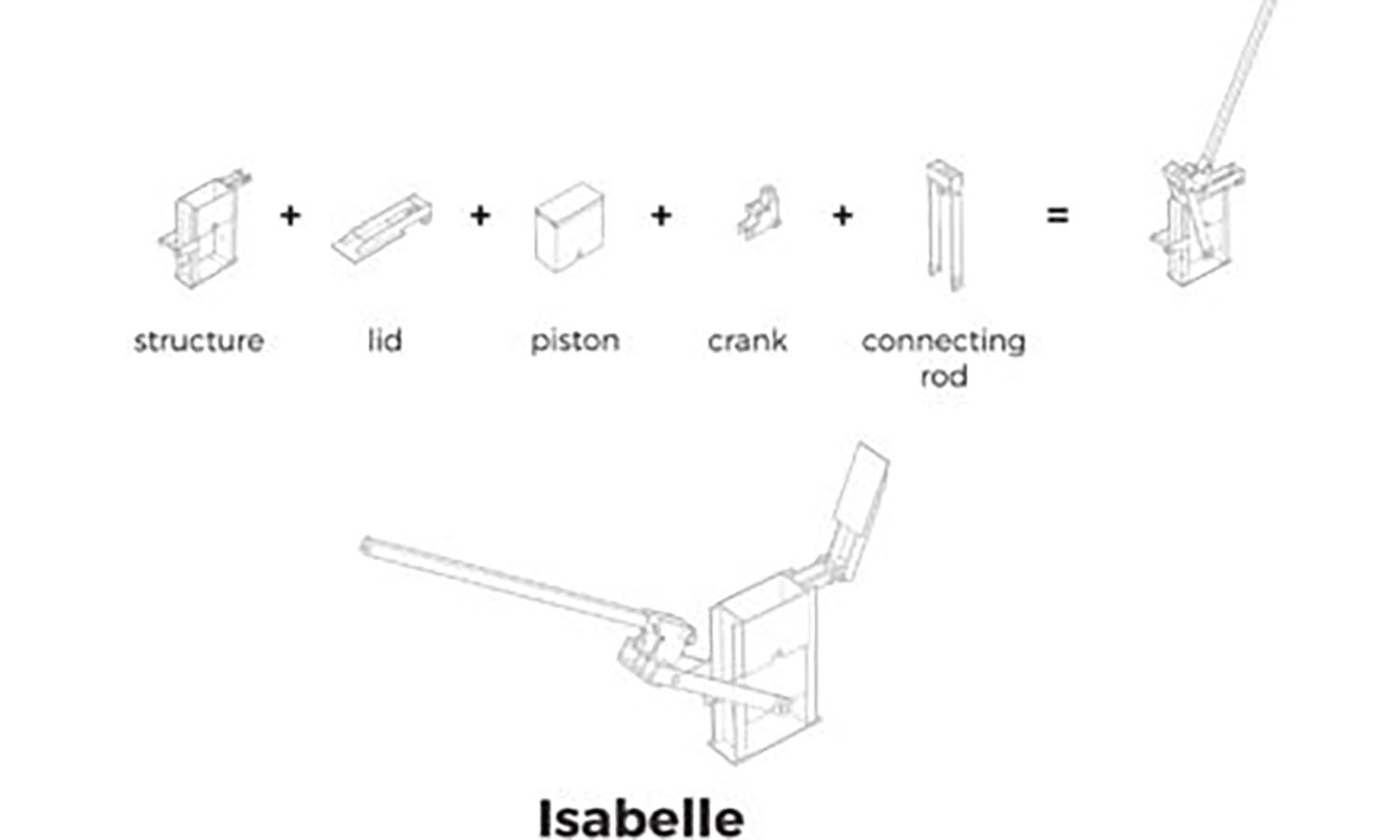

With the second prototype, we tried an new way to conceive the framework, without joining the branches at the same point, because it wasn’t actually possible to realize with the CNC machine. Here, it’s a removable system, as a kit. But it needs more materials, more branches to be stable.

Final prototype

The final prototype is a system which is foldable and transportable. It consists of an interlocking of repeated pieces of wood, which once deployed are forming the structure of the boat.

Problems :

- It needs too many differents pieces to be build

- The implementation of the boat is too complicated and requires too much time

Prototype 2.0

Reflections

At this moment of the process, we realized we had to replace ourselves in the scenario, to cope the reality of the project, the existing difficulties, the context, etc. To come back to a simpler project with some main constraints :

- Practical : to fold and unfold it easily

- Storable : to store it easily

- Comfortable : to be able to stay in it comfortably for some days thanks to a flat bottom

- Scaled : for a family : 2 adults and 2 children

References

Bambou tray / Origami / Woodskin

We started to study the project with the help of the origami technique

Contacts

In that moment of the project, we were trying to understand how to make patterns on wood. So, we got in contact with Anthony Fragale, a former student of the faculty of architecture of ULB and also former student of DFS. He helped us figure out how we should draw patterns on wood and also made us focus on one unique form.

Also, we met David Jushpe, a sailor, builder and creative. He helped us to understand the different materialities existing. To choose the right wood for our project, a wood which woudl be waterproof, flexible and solid. He also explained to us the differents assembling techniques to realise our boat.

Skype with Kerala

Later, we had a skype with fablabs of Kerala, which was again an interesting discussion. After the presentation of our project, they showed their interest, but also shared their doubts. We had some new informations to take into account :

- The boat must be solid, because a lot of boats have been destroyed because of invisibles obstacles in the water.

- There is a need to lead correctly the boat because of hiding and sharped objects under water.

Thanks to this discussion, we know we definitely had to use the wood as a solid material for our boat.

Final prototype

Conserving our criteria of a foldable and transportable boat, we wanted to come back to a simpler system. We began to work with a simple sheet of paper, using the origami technique to shape our model. Then we realized it was possible to produce a boat with the help of a single sheet of paper. So we started with the idea to use a single sheet/plank of wood to realize the project.

- Wood’s plank with standards dimensions (244×122)

- The system folds itself from the outside till the inside (traction)

Prototype 3.0

Contact

We started exchanging informations frequently with Daniel del Pozo, by phone and email. He is a carpenter and a fireman in South-East of France.

Thanks to Daniel’s professional knowledges, we headed for a well-known boat reference in the rivers of the South of France: the « Nego Chin ». Daniel explained how this type of boat works and all the features that its shape provides. This allowed us to move forward on our template and gradually improve it by sharing our various prototypes during our exchanges. Daniel was a great help in terms of the optimal shape of the boat. In addition, he is now very enthusiastic about the idea of our project and would like to create a collaboration between our work on the boat here at the ULB fablab and the Isle-sur-la-Sorgue fire brigade so that they can reproduce our project and use it in a professional way.

Reference

Nego Chin: It consists on a small flat-bottomed boat used mainly by fishermen on the rivers of southeastern France. It is also used by firemen during floods. It is a light, fast and handy boat.

Prototypes

Final prototype

The Nego Chin allowed us to analyze different boat techniques and to understand the realization of this one as well as its shape. We therefore recreated the boat’s pattern and adapted it to our criteria in order to obtain an ergonomics relevant to the project.

- Conservation of a single sheet of wood

- Abandoning the folding side

- Assembly of wooden parts

The second step was to focus more on sealing techniques. Indeed, in this prototype, the boat’s pattern divides the board into 4 pieces of wood. We then tried different sealing techniques in order to connect the pieces as well as possible while maintaining a waterproof joint. The result was unsuccessful.

- Stitch and glue: Assembly technique of boats whose process requires copper or plastic wire (stitch) then glued by joints made of epoxy resin added with a filler (glue)

- Tape Technique: The second technique consists of assembling the boards by using a waterproof tape that is resistant due to the fibres present in the tape. This technique has advantages because it is waterproof, resistant and economical

Prototype 4.0

Reference

Oru Kayak : It consists on a foldable and transportable kayak. The project is inspired by the origami technique in order to fold the project to the maximum and to be able to store it easily in a bag.

We revisited this project to study the drawing. Indeed, its folding efficiency is due to the pattern created on the polypropylene sheet.

Reflections

After reflection, we felt the desire to keep the innovative side of the project: a foldable and easily transportable structure.

Therefore, based on our latest pattern, we considered combining wood and textile in order to have rigidity/strength and at the same time allow flexibility. We therefore imagined a folding project based on the last pattern made.

While working on the model, we realized that we were always working in traction (external to internal folding) but that it would also be possible to perform the compression work (internal to external folding). In addition, the model allowed us to analyze the shape and realize that it needed to evolve more.

Indeed, while working on the model with the compression way, the pattern is automatically drawn and brings us on a triangular base. We also noticed that we could improve the prototype by working on symmetry. This symmetry allows us to fold the prototype and have a more foldable and easily transportable boat.

Prototypes

Maquette

Prototype 1

Prototype 1 / Scale 1/1

Material :

- MDF wood, thickness 3mm

- Bicycle inner tube: rubber 5cm wide (unrolled)

- Bolts M4 16mm

- Wooden slat 2cm wide / 3mm thick

Rubber is fixed to the wood by means of a wooden lamella fixed to the rubber by bolts.

Problems / Findings :

- Materials are not perfectly at the good scale

- Rubber strip too narrow, we need a wider width to leave slack between the two wooden boards. -> min. 7cm, max. 10cm

- Bolts too long for this thickness of wood. The bolts come out of the wood, you need a more suitable size

- For the next 1/1 scale prototype, a wood thickness of 6mm and bolts of 20mm would be required

- But first seen the equipment, willingness to test at 1/2 scale

- In addition, we realized that the boat’s curve was not good. The curve started from the base of the edge but finally, you have to start the curve at a little more than half of the board.

Prototype 2

Prototype 2 // Scale 1/2

Material

- MDF wood, thickness 3mm

- Bicycle inner tube: rubber 5cm wide (unrolled)

- Bolts?????

- Wooden slats 1cm wide / 3mm thick

After a first test, we improve our construction method by working on a prototype on a scale of 1/2. Now we have clarified the phased implementation of the prototype.

Half part of the boat : plank of wood on the ground

The rubber is fixed on both boards with bolts

Problem with the junction of the two different rubber bands on the central joint of the boat

To face that, we had three different possibilites :

1) To make a piece of patterned wood to fix it but still keep flexibility -> It did’nt work

2) To create a whole piece of rubber (sort of an H), but it would cost a lot and waste a lot of rubber out of one sheet.

3) To glue the two bands of rubber -> It works.

Problems / Observation

- Although the 5cm wide rubber is more suitable for the 1/2 scale, it should be a little wider, to leave some slack and allow the flexibility of the system

- Do not allow too much distance between the bolts

- The boat’s curve is better and doesn’t allow water to come in anymore

- The fixing of the joint between the two central boards is complicated, superposed joints create a possible gap and would allow water to come in

- We have to figure out how to make a good central joint still able to fold.

Final prototype

The final prototype consists of a boat made of MDF 6mm and rubber coming from bicycle inner tube. Everything is fixed with lamellas of wood ans bolts.

The boat is light, easy to carry, foldable and unfoldable.

The whole system is working with « compression », which means that the boat takes form when it’s pushed from the inside until the outside, thanks to a bamboo stick.

- Compression system

- Materials :

- MDF 6mm (2 planks of 122×61: We adapt to the different CNC machines)

- Rubber (bicycle inner tube)

- Bolts M4 20mm

- Bamboo stick

Regarding the different materials, we choose them for different reasons each one.The MDF is a cheap material, accessible and it helps us to have a good solidity and at the same time a good flexibility. Plus dimensions of the planks of wood are matching the ones used by the CNC machine.

Then, the rubber is a cheap material, which can be find easily in Kerala, as it is 91 percent of the national production culture in India. Plus it has a good flexibility, elasticity and it is waterproof.

Except where otherwise noted, this work by ULB / DFS-Q1 / 2018-2019 is licensed under a

Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.