Final project : Bamboo structure for emergency camps

Team: Eloïse et Eugénie

Light-weight structure composed of bamboo sticks assembled by 3D printed items using the Fablab network.

Project Summary

After the floods in Kerala, we were particularly chocked by the precarious situation in the emergency camps: people were crowded, they had no privacy and the main organisation in the camps was difficult to handle. Therefore, our project is to create flexible wall partition in order to give more privacy to the victims and structure to the camps.

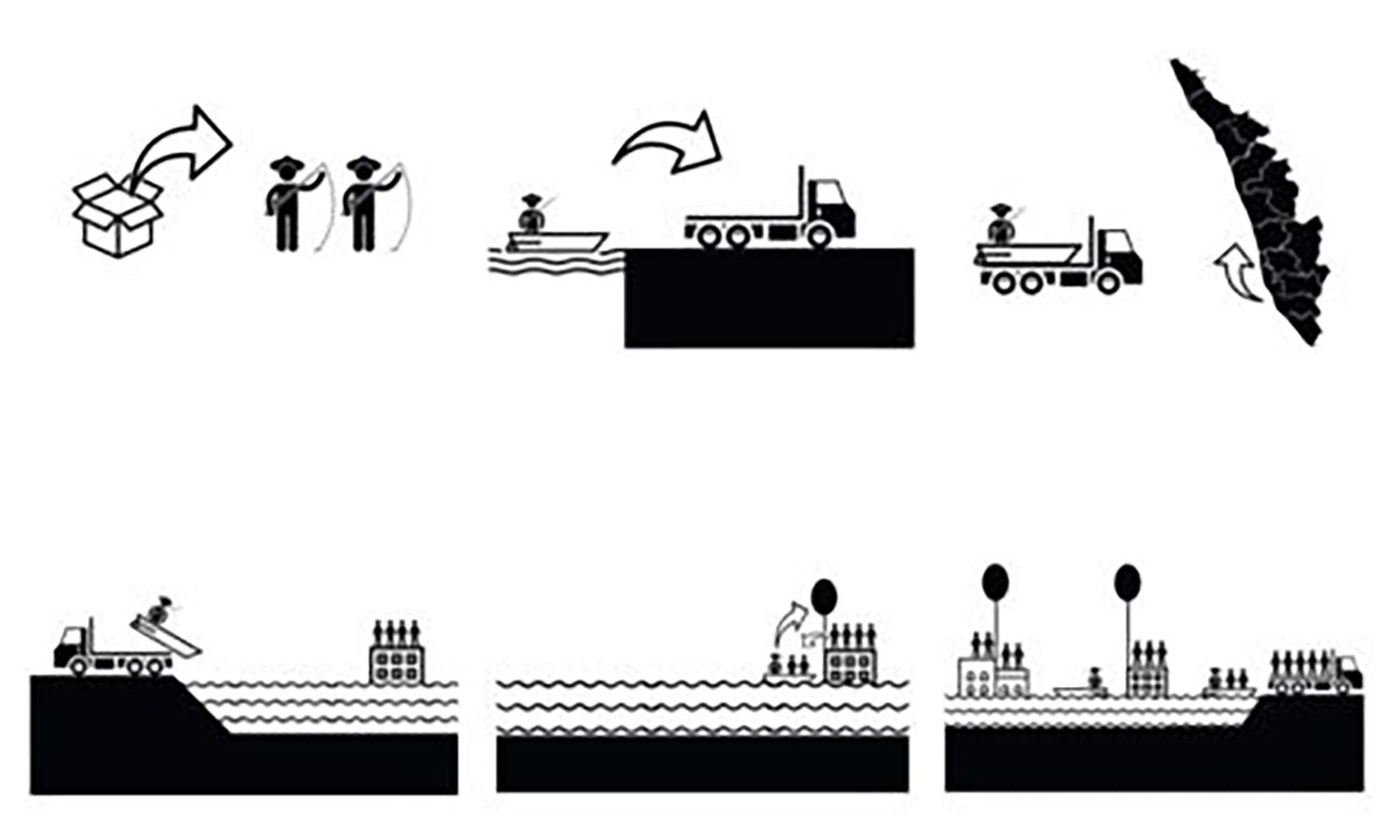

The IOM organization provides during disasters a kit to the victims in emergency camps. This kit is a plastic bag that includes: a mosquito net, blankets, a camping mat, a kitchen kit, plastic sheeting and a 30 meters long rope. We aim to complete this kit with a simple, stable, lightweight and easily to construct wall partition.

Our wall partition structure is composed of bamboo sticks and assembled by 3D printed items. A rope that passes though the corners of the structure holds it in tensegrity. Sarees (traditional Indian women clothing) will be used to cover the structure to make the space welcoming and intimate. These will be hooked to the rope holding the structure by laser-cut wooden pegs.

The production mode is quite easy: the 3D printed items are printed and the pegs are laser-cut in Indian FabLabs and put in the IOM kit, the rope is already in the kit, the elastic bands are added to the kit, the Sarees are donated by the population and the bamboos are provided by “Kerala State Bamboo Corporation Ltd”. Then, the structures are assembled by the people on site and can be put together to form a set of private space.

Moreover, the purpose of the project is to be able to provide any emergency camps in the world. The project could be used in any camps after a climate disaster in the world and be spread by the IOM organization.

Storyboard

Installation manual

Source and reference

Source

We talked to several person during all our project process. This helped us a lot to evolve in many situations.

Firstly, we asked general informations about the situation in the emergency camps to Michäël Gäthögö. He gave us a report of the IOM organization. It was the key of our concept.

Then we tried to contact IOM by email but they didn’t answer yet.

The third person that helped us was an artist named Paty Sonville. To experience other ideas, we wanted to test matrix and steel fabric. Paty gave us professional advices to go further.

Reference

Our first reference was Shigeru Ban camps. We love the refine way he structures the space.

We also took many inspiration in typical bamboo structures, especially bamboo scaffolding in India.

3D image of our prototype

STL file of our prototype

Process : Bamboo structure for emergency camps

Team: Eloïse et Eugénie

Light-weight structure composed of bamboo sticks assembled by 3D printed items using the Fablab network.

Process

At first, we did some research to find the purpose of our project. We were immediately choked by the condition in the camps. So, we decided to find solutions to create more intimacy in the camps with a flexible wall partition.

We started developing prototypes. The first one was an origami cardboard structure: the material wasn’t adapted, and the loss of material was too excessive.

Then, we thought at a cardboard shelter, but it was too heavy, and the structure took too much space.

We also tried a carboard folding wall but the articulations between each structure was difficult to set up.

The last prototype in cardboard was a retractable column. This system was too heavy and didn’t structure enough the camp.

In the end, we realised that the cardboard was too fragile and not appropriate to the project.

After doing these prototypes, we decided to go further in our research to identify the real needs. The Indians may have a different vision of intimacy. Most houses are placed around a loggia (inner courtyard). Their homes are also futured with a central space. Most Indian people find that the important thing is to live with their family. The most popular materials are bamboo and colourful fabrics. The natural light is also important in the composition of the houses.

With these researches, we decided to use bamboo which is a local, solid and flexible product. We also decided to use Sarees to give intimacy and colour to the camp. Plus, Saree is a well-known clothing that was massively donated during the floods.

To have a light but also a solid structure, we decided to make a structure composed of bamboo maintained in tensegrity. The bamboos are assembled by a 3D printed item, an elastic band and a rope.

The first 3D printed prototype had a base and 2 tubes but was heavy and not modular.

The second one had 4 tubes to make it modular but didn’t allow the structure to be stable. The rope couldn’t pass through the plastic piece.

So, for the last one we decided to add a hole to allow the rope to pass through.

This prototype is stable and solid, but the printing time is too long. To set up one camp, we need 900 hours (one month) with one printer. We designed another wood prototype using a CNC. But this one was too heavy for the structure.

In order to reduce the printing time, we did some research to make a matrix out of our object. But after we have talked to a professional, the time will not be reduced. We are still exploring other ideas.