Project repository : water-filter

Final project: Water Filter

<

p dir= »auto »>team: Marie-Melissa Kennes, Aurore Willems, Cindy De Sousa Oliveira, Nicolaos Bibissidis

Water filter using wood componant for filtration and easy to make.

Project Summary

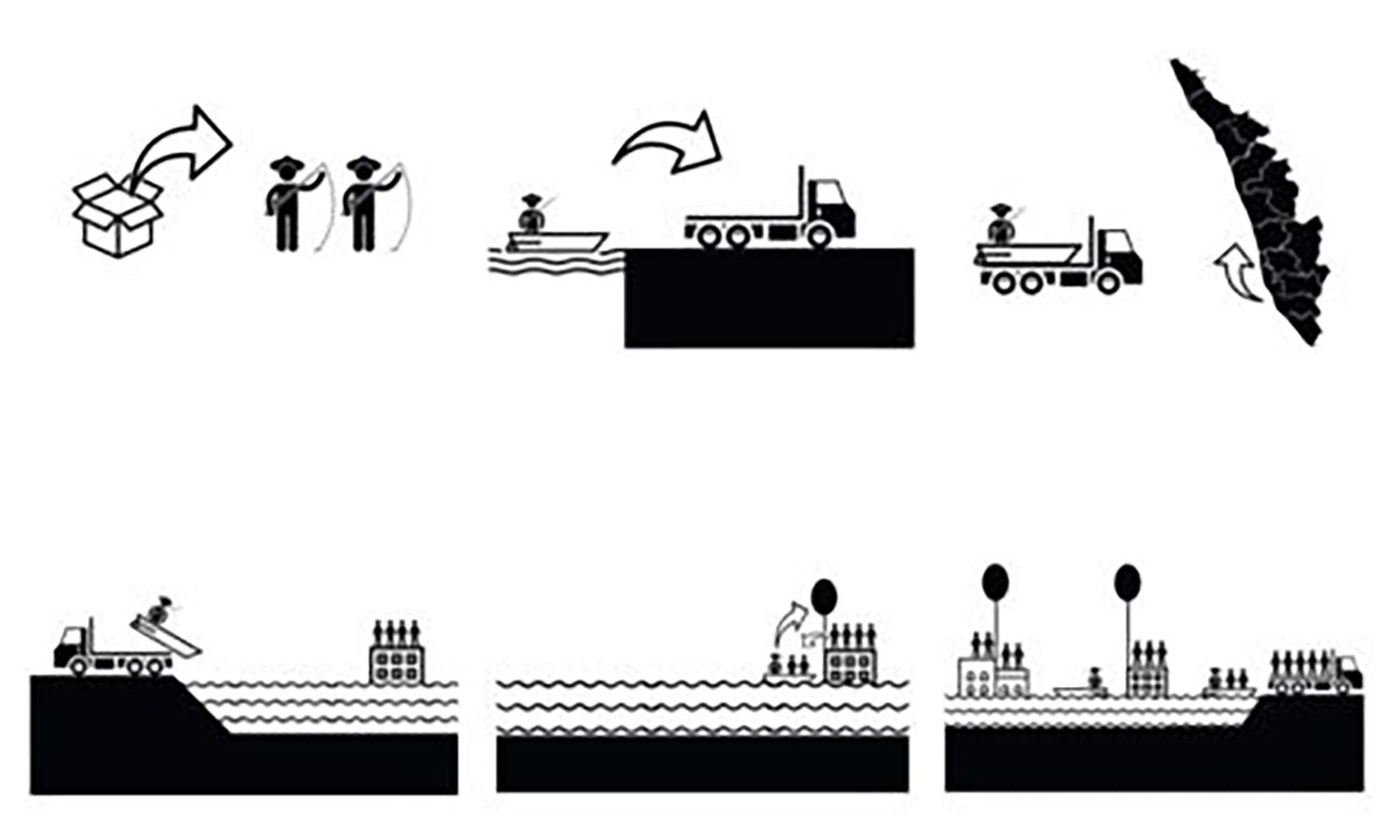

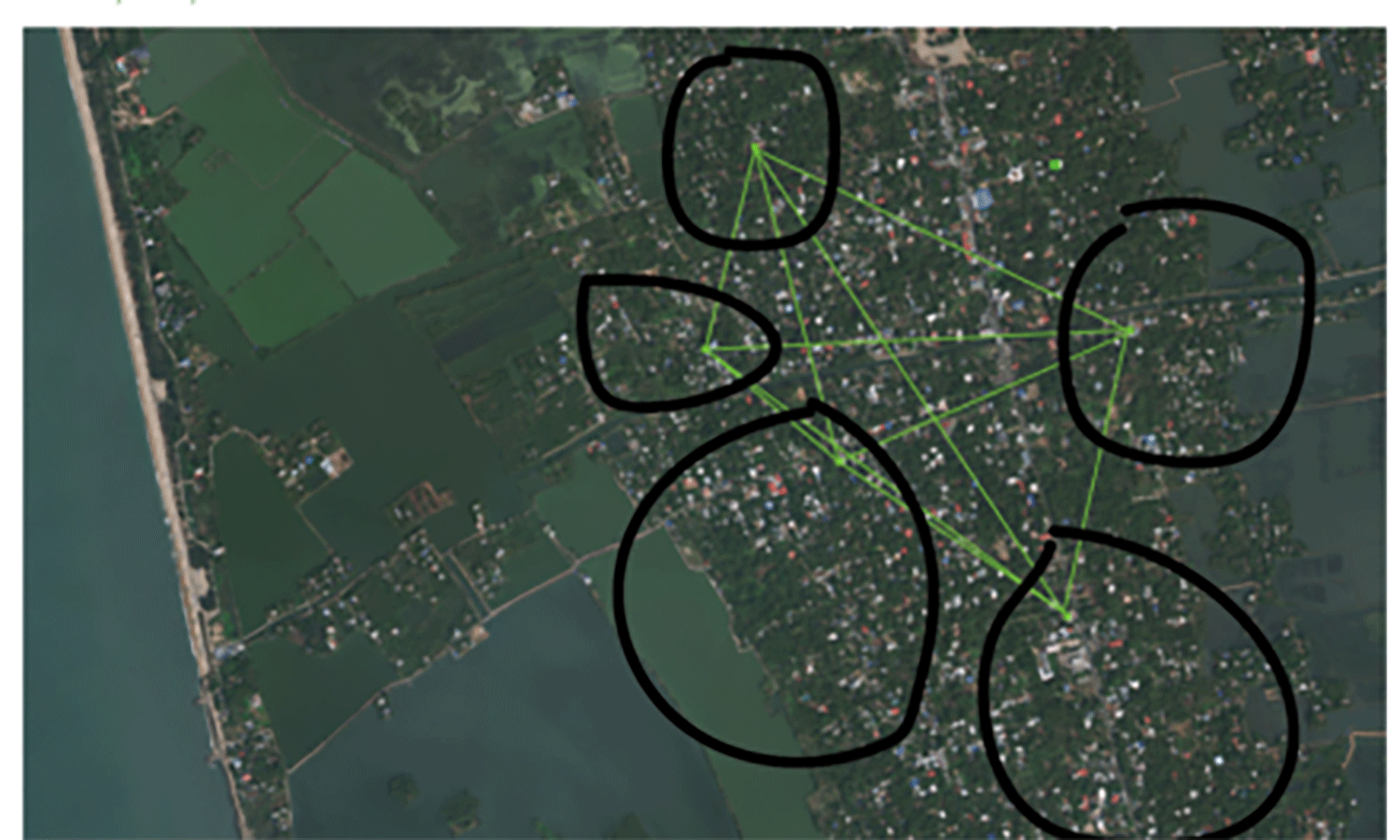

During the floods in Kerala in August 2018, water filters were sent to the north of the region. Due to the problems caused by the flood, these filters could not be transported to the south. Our idea is to be able to build its own filter to overcome a lack of outside help. However, the filter can be used at any time because there is a lack of access to drinking water in southern countries. It can be used before, during, and after a disaster.

Our prototype consists of a plastic bottle, a flexible PVC tube and a wooden cap previously carved with the CNC inserted into each other. Since the wood has a porous structure, the process consists in filtering water through this piece of wood by pressure. The pressure could be get by mechanical work or gravity. This filter is primarily for single use nevertheless improvements could be made to filter a larger amount of water in the future.

Storyboard

Tutorial

we need:

- valve for rim:

- bottle of soft drink:

- flexible (and transparent) pvc tube:

- clamp:

- Teflon:

- cord:

- manual or electric bicycle pump:

Here you will find the filter mounting link:

filter construction

Bibliography

- Michaels.S.H.Boutilier, “Water Filtration Using Plant Xylem”, Plos one, Vol.9, Février 2014

- Susane Espino, “Mind the bubbles: achieving stable measurements of maximum hydraulic conductivity through woody plant souples”, Journal of Experimental Botanes, Vol.62, n°3, pp 1119-1132, 2011

- J.J.Simonis, “Manufacturing a low-cost ceramic water filter and filter sustem for the elimination of common pathogenic bacteria”, physics and chemistry of the earth, Vol 50-52, 269-276, 2012

- Sobsey.M, “Fiche de produit sur la conservation et traitement de l’eau à domicile:Lifestrauw”, CAWST, 2010

- Shahin Homaeigotar, “Graphène membranes for water desalination”, VPG Asia material, Vol 9, P 427, 2017

- Rubin Shmuisky, Toust Products and woods science an introduction, sixth edition, witez-Blackwell,2011,477p

Process our water filter

Haugimont process

We were shocked by the paradox that exists between the excess water causing countless damage and the lack of access to drinking water after such a disaster.

Faced with this problem, we decided to worry about water treatment. For this, our project is to create water filters to have drinking water directly during the disaster and during long stays in the camps. The biggest challenge is that these filters must be easy to build and inexpensive. That’s why we promote the use of waste as a resource.

- The wood filter

This filter consists of supplying the population with water during the disaster. For this, we started from an existing project (« wood filter », blog dfs 2017) that we modified and put in the context of Kerala. This process consists in filtering water through a piece of a branch of wood.

We first focused on the wooden « stopper ». The idea is to tie two bottles with this cap and let the water flow from one bottle to the other bottle (container) through the obstacle.

Materials:

- Branches or wooden log

- Plastic bottles

- Rubber of a tire

- Balloon

the cork

To make the water drinkable, all impurities must be removed; bacteria that measure 0.2 μm long, viruses, and other wastes. The filter must therefore have holes smaller than 0.2μm. According to a study by MIT, pine contains smaller pores than others and can therefore filter water up to 99.99%. We learned about the different woods in Kerala and in our regions so that we could test at FabLab. Since pine is not present in Kerala, we have conducted research on wood available in different parts of the world. We soon realized that there was no « universal wood ».

Conifers have the most appropriate characteristics for the manufacture of this tool. During our stay we had access to spruce. We got a branch and some logs from those felled trees.

We did a test with a branch of spruce as well as with the piece of trunk of spruce.

The piece of trunk:

For the following, it was necessary to cut the trunk with the circular saw to have a smaller thickness and adapted to the length of the « drill »

We extracted the plugs from the wood samples obtained with the CNC.

The part of the CNC piercing, had a length less than the log. We had to finish cutting by hand.

We extracted 12 caps with a single spruce log.

Branch:

After removing the bark manually, we cut different lengths with a circular saw

Water Resistance

Once the bottles were connected via a « filter plug », it was necessary to find a solution to make the intersection waterproof.

For this, we used the rubber of a recovered tire and the end of a balloon. We cut circles on the rubber with the laser, to place them between the two necks of the bottles.

A small sizing error and too much elasticity meant that we had to wind the rubber band three times.

To ensure a better sealing, we covered the necks and the rubber band by the end of the balloon.

Test and Results

We did a first test with a plug that was close to the heart of the spruce log, and after a night of waiting, not a drop has passed …

The next day we tried with a cork much further away, and after 4 hours of waiting, +/- 10 ml of clear water flowed.

In our opinion, the water did not flow because the heart of the tree is much denser.

Continued…

Since the water flows very slowly, we will install a system to put pressure. We will start with a bike pump and probably use the recovered tire pipette to attach the pump cable to the top or side of the filter. To seal the joint of this binding, we think to make a glue based on polystyrene and gasoline.

After Haugimont

After the week spent at Haugimont, we reproduced the prototype that had been made on site.

It consisted of two plastic water bottles, a wooden stopper of 2.1 cm in diameter and a height of 3.5 cm. This comes from a slice of a spruce trunk cut from the CNC. We also used rubber gaskets cut from a tube with the laser and used a balloon for sealing. The water being filtered by simple hydrostatic pressure. The wood used (spruce) for this filter also came from Haugimont. For reasons not yet fully understood, no flow was observed on this filter which was reproduced.

Subsequently another prototype using compressed air was proposed to us by Denis.

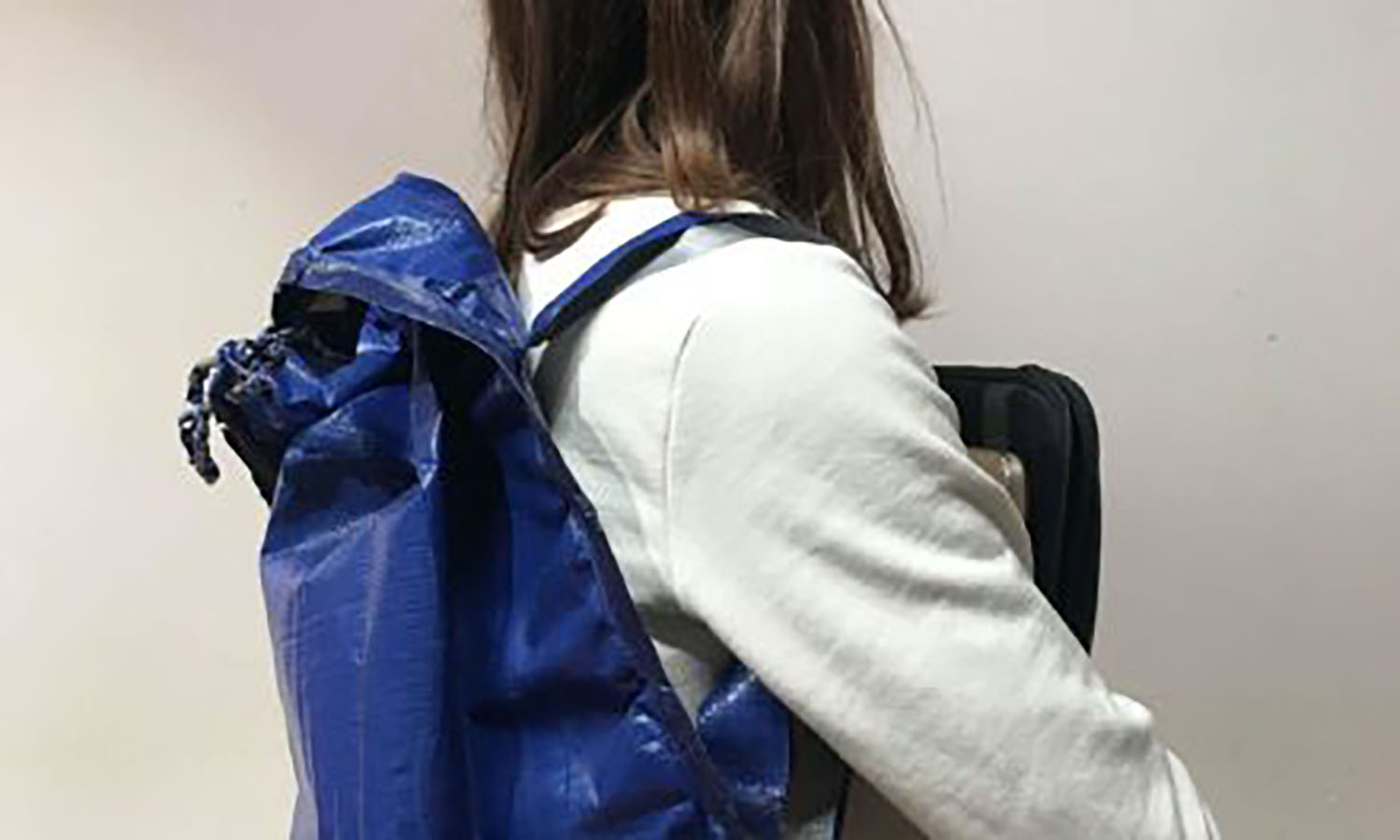

This prototype consisted of a plastic bottle, rubber from an inner tube, a wheelbarrow, transparent flexible pvc tubes, a plastic T-connector, pipe clamps, a piece of a branch and teflon for sealing.

This prototype filtered water containing Chinese ink and had two plugs of filtering wood. This prototype has shown its effectiveness. The water that came out was clear. The Chinese ink at the size of 50-100 nanometer is +/- the size of a bacterium, it has been proved with this test that the bacteria can be filtered with spruce.

We have reproduced the model in a simplified way.

We tested the flow:

A drop came out every 25 seconds

1ml = 20 drops

1ml = 500 seconds

1l = 500,000 seconds (= 128H)

3l = 17 days

However, we are not sure of the result because the calculation does not take into account the pressure.

A little bit of physics!

It’s possible to predict the evolution of the debit Q in the case of filtration by gravitation.

So if we plot this expression Q in time t, we get:

We can see we need a lot of time to observe the exponential decay in time of the debit. We can explain this by the fact that K is very small. Futhermore, if the section S of the bottle is big compared to the section A of the cork, this effect will be accentued.

So we can consider the debit is constant on 24 hour. It make predictions easier.

Meeting with a bioengeneer

Subsequently we saw Professor Charles De Cannière, a bioengineer specialized in wood structure. He explained to us the difference between coniferous and hardwoods, the cellular organization of wood and by where filtration water occur.

It would be easier to use softwood, the latter having a larger part of the trunk and potentially filtering areas that could be identified as sapwood. Sapwood is the area that consists of living cells and these are the ones that have filtering capabilities.

These cells are very long and very thin cells, in which we find punctuation. The cells being closed at the ends, they can only communicate with these other punctuations otherwise called orifices.

This being a room, it defines a room space. The water will pass through this orifice through this primary wall which is porous (the torus). According to Cannière Charles this is where the water is filtered.

He was also able to respond to other issues such as the issue of wood preservation. The answer is simple; it can be kept in water but it must not touch the surface. The wood must therefore be completely immersed in water and can not come into contact with the air.

Another question was the desaturation of wood used as a filter. Unfortunately according to Charles De Cannière, it seems unlikely. It may be possible to do this but it will cause a riot of energy and material that we had better change.

Meeting with ecology of aquatic systems specialist

After our interview, he advised us to contact Pierre Servais, professor and director of the aquatic systems ecology department at the ULB. What we have done.

We asked him how to detect the potability of the water.

He first explained that it must be free of pathogenic microorganisms. These can be of different types: we find pathogenic bacteria (ex: salmonella, erichia coli, Vibrio cholerae, …), pathogenic viruses (ex: hepatitis A virus, hepatitis E virus , enteroviruses, …) and parasitic protozoa (eg gardia, cryptosporidium, …).

What characterizes all these pathogenic micro-organisms is that their main origin is the digestive tract of humans and animals and they are excreted with feces. The water will be contaminated when it receives these feces. The water receives these materials at the end of the treatment plants (although a good part of the micro-organic materials have been treated, it still remains) and during soil runoff. As India has very little sanitation, it is understandable that water is highly contaminated with pathogenic micro-organisms.

They last well in the body for 2 reasons. First, they are in a constant temperature environment (about 37 degrees) and second, they are not subjected to ultraviolet radiation. In the aquatic environment, these microorganisms survive relatively poorly.

So the first thing to know is how the water is polluted. This will depend on where the water is taken. There is therefore an infinity of water quality.

Then he explained to us the simplest technique of control of the micro-biological qualities of water. It is based on the concept of indicator of faecal contamination: that is to say we will seek to enumerate groups of bacteria known to be very abundant in feces. This is the case, for example, of erichia coli, which is the most widely used indicator of faecal contamination. If we know that there is such a concentration of erichia coli in water, there will be such a level of risk of presence of other pathogenic microorganisms. In the regulations, water is considered safe if there is 0 ml of erichia coli in 100ml of water.

To detect their presence, the technique consists in carrying out a bacteriological culture in a petri dish of a water sample before and after filtration.

The water is filtered through a sterile filter that has a porosity of 0.2 or 0.4 mircons. This porosity does not let the bacteria pass. So these will be deposited on the filter. Then, this filter is placed on a petri dish which contains a culture medium adapted to erichia coli. The bacteria will multiply and after 24 or 48 hours, nova can count the number of colonies. Each erichia coli will have given rise to a colony. From the number of colonies and knowing the volume that we have filtered, we will be able to recalculate the concentration of erichia coli.

Nevertheless, bacterial culture requires technical means and experimental knowledge that we do not have. Due to lack of time, Professor Servais can not help us with our tests in his laboratory. He advised us to turn to a private company for our tests. If we do not find the way to test our filter with bacteria, we will have to be satisfied with pigments having the same size as this one.

Then we produce new prototypes in the laboratory.

Prototypes

Test 1:

We have laser cut a hole in a plastic bottle that will be used to insert the pipette of the tube.

We inserted this pipette into the can by adding a rubber seal inside and outside the can. We fixed everything with a hexagonal screw head.

We placed rubber between the cap of the can and the pipe to test the tightness.

RESULT TEST 1:

The seal was not conclusive since the water leaked at the plug.

In addition, the water did not flow because the height of the cap is too large (3.5cm).

TEST 2:

We removed the seal at the plug and replaced it with a plastic plug.

RESULTS TEST 2:

The result was not conclusive because the wooden cap that we used is a wood cut 4 weeks ago. It was not stored in water and so it lost its physical properties.

TEST 3:

We created a plug adapter with the 3D printer. We created 2 because the first was too small.

We added teflon between the wood and the pipe to make

sure of the tightness.

RESULTS TEST 3:

After exerting a pressure of 2 bars, the can to exploded …

We concluded that the bottles must be sufficiently resistant to pressure. Bottles for soft drinks are more resistant than bottles used as a container for soft drinks.

4 EME TEST:

We also added teflon at the can stopper.

We exerted pressure with a car compressor.

We used a wood that was kept in water and reduced the height of the cork (about 1.4 cm).

RESULTS TEST 4:

We got 12.23 cl of water in 9.12 minutes.

After one week, the filtered water in Run 4 turned yellow. She had a smell of sap and a viscous appearance. We saw again Charles de Cannière, who explained us that it is certainly a system of defense of wood. The water we used was kept for about a month. If in a future use, we also use a wood preserved in water, it will be necessary to steam the wood and spend 2 to 3 days in the oven between 102 and 104 degrees to avoid this phenomenon.

As we can see in the picture, the wood not preserved in the water has been dead after a few weeks.

The prototype that we realized before the pre-jury consisted of:

a soft drink bottle (better resistant to pressure)

Rather than using a tube pipette and rubber for sealing, we simply use a tube valve.

We used apple tree as freshly harvested wood because we wanted to test the filtration with a hardwood.

At the level of the filter cap: We returned to the basic structure, with clamps.

We tested the flow rate.

RESULT:

- Waterproof ok

- Flow rate greater than previous results

- We have thought about other cork prototypes for the rest of our project.

With the new prototype, we tried to determine the value of the constant K of our sample. But we had technical problem and we had only 3 points. Not enough for a good analyse.

ANALYSIS BEFORE / AFTER LABORATORY FILTRATION

We went to have the water analyzed before and after filtration in a laboratory at the Paul Lambin Institute.

Before the analysis, we went to collect water from the ponds of ixèlés in a sterile container.

Then we were shown the process to analyze the potential pathogens present in the water.

First, we chose a culture medium that gives preference to enrichia coli.

Then we proceed to inclusions; that is to say, we will look for the total seeds. If there are too many bacteria, dilutions are made. We divide the bacteria to better recognize them.

In the environment, 5ml of dilution water is taken and 1ml is inserted into the petri dish.

Then we can move to inclusion; the culture medium is poured into the petri dishes containing the diluted water. We have petri dishes before and after filtration. In addition, there are boxes that will go to 22 ° C (at room temperature) and others to 37 ° C (indicates the human condition).

We can now move to the filtration station. On the filter strip, sterilized funnels are inserted. Once the culture medium has passed from the liquid state to the solid state, filter membranes are inserted therein.

We can now switch to filtration. The filter is then recovered and placed in the petri dish.

It will be necessary to wait 24 hours for the preserved boxes with a temperature of 37 ° C and 48 hours for those conserved with 22 ° C.

New test of flow

We compared the flow of a softwood to that of a hardwood (an apple tree) by testing 3 different wooden cap heights (2cm – 1.2cm – 0.7cm).

We exerted 5 different pressures and calculated the flow time for 10ml of harvested water.

Here are the results obtained:

Softwood – 2 cm:

1 bar: 4’40 »

1.3 bar: 1’02 »

1.4 bar: 1’00 »

1,6 bar: 20 »

1.8 bar: 11 »

Softwood – 1.2 cm:

1.7 bar: 9’56 »

NB: Below and above 1.7 bar, the water did not flow.

Softwood – 0.7 cm:

NB: The water has not passed at all.

The system exploded (not the bottle itself but the hose came out of the bottle) when we arrived at 3 bar.

Hardwood – 2 cm:

0.4 bar: 51 »

0.8 bar: 31 »

1 bar: 12 »

1.2 bar: 12 »

1.5 bar: 10 »

Hardwood – 1.2 cm:

0.8 bar: 9 »

1 bar: 5 »

1.1 bar: 5 »

1.2 bar: 4 »

1.3 bar: 3 »

Hardwood – 0.7 cm:

0.6 bar: 1’37 »

0.8 bar: 50 »

1 bar: 55 »

1.2 bar: 29 »

1.4 bar: 11 »

Then we tested the filtration of these plugs with Chinese ink dilute in water. Unfortunately, the water came out black. We concluded that the wood, cut 2 weeks ago, to lose its physical properties. And the data colected earier are false. We should have kept it in water directly after cutting. We can not rely on these results.

3D cap

Following our previous sketches of the cap, we wanted to deepen the question of the 3D print plug. Inside of this cap we just stuck the wooden cap , who was cut by the CNC.

At first the bottleneck of a sparkling plastic bottle was measured with a latte with a screen. Measurements such as, inside diameter, outside diameter, neck height, thickness of faults and slope were measured.

Those measurements made it possible to draw the first prototype. It was drawn on the Autocad software for the plan, elevation and section and then on the Sketch Up Pro software for the 3D model.

Then the printing of two slightly different prototypes were launched on the 3D printer « Ultimaker2 + ».

Unfortunately after 5h prints for both plugs print at the same time, the result was not very conclusive.

The prototypes were too fragile and did not print well.

Several tests will follow hoping to have the right one for the final jury.

Except where otherwise noted, this work by ULB / DFS-Q1 / 2018-2019 is licensed under a

Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.